Copper Nickel Steel 70/30 Fittings Manufacturer in India

HOME → Our Products → Fittings→ Copper Nickel Steel Products → Copper Nickel 70/30 Fittings Manufacturer

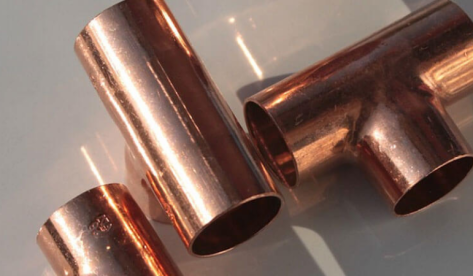

Copper Nickel 70/30 Reducer, ANSI B16.9 Cupro Nickel 70 / 30 Butt weld Fittings, ASTM B466 70-30 Cu-Ni Pipe Elbow, Cupro Nickel 2.0882 Buttweld Elbow, Cu-Ni C71500 Pipe Fittings, Cu-Ni 70-30 Buttweld Fittings, Copper Nickel 70 / 30 Equal Tee, Copper Nickel 70/30 Pipe Fittings Supplier in Mumbai, India.

Copper Nickel 70-30 Pipe Cap Stockist, CuNi 70/30 Stub End, ASME SB 466 Cupro Nickel 70/30 Cross, Cu-Ni 70/30 Buttweld Fittings, Cu-Ni 70/30 Buttweld Fittings, Cu-Ni 70/30 Buttweld Fittings, Cu-Ni 70/30 Buttweld Fittings, Cu-Ni 70/30 Buttweld Fitting Exporter of Cu-Ni 70/30 Pipe Bend and Cu-Ni 70/30 LR Elbow in India.

Cu-Ni 70/30 Welded Pipe Fittings, CuNi DIN 2.0882 SR Elbow, Copper Nickel 70/30 Seamless Butt weld Fittings Manufacturer in India.

Table of Content

- Standard Specification

- Chemical Composition

- Mechanical Properties

- Equivalent Grades for 70/30 Cupro Nickel Pipe Fitting

- Markings On The Cupro Nickel 70/30 Butt weld Pipe Fittings

- Cupro Nickel 70/30 Pipe Fittings Specifications

- Cupro Nickel 70/30 Pipe Fittings Chemical Composition

- Cupro Nickel 70/30 Buttweld Fittings Mechanical Properties

Manufacturer & Supplier of Copper Nickel Steel 70/30 Fittings

Mahavir Metals India is a reputable dealer of copper forged fittings. We keep a stock of the most popular grade forged fittings in different designations, standards, dimensions, and thicknesses. Respect with national and international standards product reaches the top quality. Our inventory has Cu 70/30 forged fittings that can be changed to meet the urgent needs of clients. The forged fittings are made up of copper and other materials in a ratio of 70 to 30%.

The supplier does quality assurance to make sure that clients get the best products. The forged fittings were tested in different ways, including mechanical tests, chemical tests, PMI tests, radiographic tests, pitting corrosion tests, visual inspection tests, and other tests. Also, fittings are finished off by a third-party inspection. Professionals oversaw the production to eliminate the risk of loss and mistakes.

Copper nickel 70 30 pipe fittings are the types of pipes that guarantee a strong resistance to corrosion and fabrications, and we are the manufacturer, the supplier, and the exporter of these fittings. Pipe fittings like this are capable of supplying a diverse array of types and ranges. On the other hand, these are offered in a variety of shapes and sizes to cater to the preferences, prerequisites, and prerequisites of the customers. This material for pipe fittings is being produced by our company in compliance with the standards of a number of different industries and in response to the particular requirements of our customer. In order to guarantee the secure packing of the product during the final stage of production, we provide pipe fitting material that has been thoroughly examined and packaged in the appropriate manner.

The resistance of our Curpo Nickel UNS C71500 70/30 Buttweld Pipe Fittings against salt water is well-known for being exceptionally large and strong throughout a wide range of conditions. Copper Nickel 70/30 Pipe Fittings are utilised extensively as the connectors for piping systems in the industries of power generation and ship building. This is because these pipe fittings have an excellent alloy absorption rate. Our CuproNickel 5D Elbows have a tensile strength of 52,000 psi, which makes them tough enough to operate in high-velocity seawaters and brackish waters. The copper and nickel content of the CuproNickel 5D Elbows is 70 percent and 30 percent, respectively. On the other hand, UNS C71500 Pipe Couplings are resistant to biofouling because they develop a protective oxide layer. They are also able to function effectively under high pressures and temperatures and in locations where turbulence is created.

Specifications of the alloy:-

Cu-NI 70/30 is a nickel and copper-based alloy that contains 70 percent copper and 30 percent nickel alloy, as well as manganese and iron alloying components. These elements are added to provide resistance to erosion and corrosion, as well as increased strength, making it an excellent choice for a variety of applications. The alloy's corrosion resistance is significantly increased in high-velocity water and dirty seawater. Without the need of any specific metals, 70/30 may be cold worked, welded, and manufactured quickly. The C75100 and CN107 designations are common specifications for the alloy.

Process of production:-

Copper Nickel Cu-Ni 70/30 (C71500) Buttweld Pipe Fittings are developed using pure raw material at our well-equipped production facility. The quality checker tests and approves the raw material for usage. The development process is carried out under the close supervision of competent experts, with the use of advanced technology and modern machinery and tools. All range fittings are designed and manufactured in accordance with industry-standard production parameters. Also, when fabricating pipe fittings, producers take into account raw material quality standards in order to create fittings that are of consistent quality.

Stock Size Range and Specifications For Cupro Nickel 70/30 Pipe Fittings

Specification : ASTM B466 / ASME SB466

Dimension Standard : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Type : Seamless / Welded / Fabricated

Chemical Composition of Cupro Nickel 70/30 Buttweld Fittings

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cupro Nickel 70/30 | 65 min | 1.0 max | 0.05 max | 29-33 max | 0.4-1.0 max | 1 max |

Mechanical Properties of Cupro Nickel 70/30 / C71500 / 2.0882 / Cu-Ni 70/30 Pipe Fittings

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Equivalent Grades for 70/30 Cupro Nickel Pipe Fitting

| STANDARD | UNS | WERKSTOFF NR. |

| Cupro Nickel 70/30 | C71500 | 2.0882 |

Markings On The Cupro Nickel 70/30 Butt weld Pipe Fittings

- Rating Designation

- Material Designation

- “WP” in grade symbol

- Grade

- Schedule number or nominal wall thickness

- Heat Code

- Manufacturer’s Name or Symbol

Cupro Nickel 70/30 Pipe Fittings Specifications

Specifications | : | ASTM B366 / ASME SB366 |

Size | : | 1/2″ to 24″ NB to 24″NB in |

Standards | : | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

Thickness | : | 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75 |

Type | : | Seamless / Welded / Fabricated |

Cupro Nickel 70/30 Pipe Fittings Chemical Composition

| Cu-Ni 70/30 | Cu | Pb | Mn | Fe | Zn | Ni |

| 65.0 min | 0.05 max | 1.0 max | 0.4-1.0 | 1 max | 29 – 33 |

Cupro Nickel 70/30 Buttweld Fittings Mechanical Properties

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 20000 psi | 50000 psi | 30 % |