Stainless Steel 904L Flanges Manufacturer in India

HOME → Our Products → Flanges → Stainless Steel Products → 904L Flanges Manufacturer

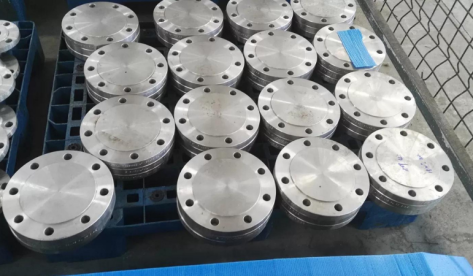

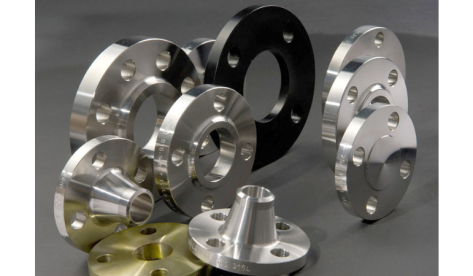

Alloy 904L Blind Flange Manufacturer, PN16 DN65 DN80 SS 904L Plate Flange Huge Stock of DIN 2576 600LB FF Type ASME SA182 SS 904L WNRF Flanges, SS DIN 1.4539 Nipo Flanges, 150# ANSI SS 904L Lap Joint Flange Weight Chart, SS DIN 1.4539 Nipo Flanges, SS DIN 1.4539 Nipo Flanges, SS

1.4539 Flanges, Stainless Steel 904L Flange, 904L Stainless Steel Flanges, ASTM A182 F904L Flange, 904L SS Plate Flanges, SS 904L Flanges, ANSI B16.5 Stainless Steel 904L Flanges, Stainless Steel 904L Pipe Flanges, UNS N08904 Flanges, SS 904L Forged Flanges, Stainless Steel 904L Flanges Manufacturer in Mumbai, India.

Table of Content

- Standard Specification

- Chemical Properties

- Mechanical Properties

- Equivalent Of 904L stainless steel Forged Flanges

- DIN 1.4539 Ring Type Joint Flanges Thermal Composition

- 904L SS Flanges Physical Properties

- DIN 1.4539 Ring Type Joint Flanges Thermal Composition

- ANSI B16.5 SS F904L RTJ Flange Dimensions Chart

- Huge Inventory Of Stainless Steel 904L Flanges

- Stainless Steel F904L Weld Neck Flange Pressure Gauge

Manufacturer & Supplier of Stainless Steel 904L Flange

The nickel chromium molybdenum alloy offers the material with excellent corrosion resistance and strength. It has good mechanical qualities as well, with a minimum yield strength of 220 MPa and a minimum tensile strength of 490 MPa. The melting point of the material is also high, at 1350 degrees Celsius. The Alloy 904L Blind Flange is used to close off the end of a pipe, usually permanently. The steel is a low-carbohydrate version of the 904 grade. This means that welding and shaping operations on these flanges are simple and without the risk of grain formation and intergranular corrosion caused by carbide precipitation during the welding process.

A plate is connected to the SS 904L Plate Flange to provide more area for welding, bolting, and other attaching methods. The flanges are manufactured to ASTM B649 specifications, with numerous standards such as ANSI, ASME, DIN, and EN. These flanges come in a variety of diameters and pressure ratings, ranging from 12 inches to 48 inches. Weld neck raised face flanges are ASME SA182 SS 904L WNRF Flanges. These flanges have welded necks and elevated faces for additional strength, and they come in pressure classifications ranging from 150 to 2500 psi and PN6 to PN64. Pharmaceutical, petrochemical, maritime, sea water, and power generating are just a few of the sectors that use these flanges. Heat exchangers, boilers, condensers, paper and pulp industries, offshore oil drilling, and chemical and sea water equipment manufacture all employ SS DIN 1.4539 Nippo Flanges. We have a wide range of SS UNS N08904 Industrial Flanges available to fit any need. For more product information and price, please contact us.

Alloy 904L Blind Flange Specification Format

Specifications List | ASTM A182 / ASME SA182 |

Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Size Chart | 1/2″ (15 NB) to 48″ (1200 NB) |

ASTM Standards | ANSI/ASME B16.5, B16.48, BS4504, B 16.47 Series A & B, BS 10, EN-1092, DIN, etc. |

Standard Flange | ANSI, ASME, BS, DIN, EN etc. |

Chemical Properties

Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

SS 904L | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

Physical Properties of SS DIN 1.4539 Nipo Flanges

Yield Strength 0.2% Offset | Ultimate Tensile Strength | Elongation in 2 in. | Hardness | ||

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 31,000 | 220 | 71,000 | 490 | 36 | 70-90 Rockwell B |

Equivalent Of 904L stainless steel Forged Flanges

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

DIN 1.4539 Ring Type Joint Flanges Thermal Composition

Properties | Metric | Imperial |

Thermal expansion coefficient (@0-100°C/32-212°F) | 10.4 µm/m°C | 5.78 µin/in°F |

Thermal conductivity | 21.6 W/mK | 150 BTU in/hr.ft².°F |

904L SS Flanges Physical Properties

Density 0.287 lbs/in3 7.95 g/cm3 Specific Heat 0.11 BTU/lb-°F (32 – 212°F) 450 J/kg-°K (0 – 100°C) Modulus of Elasticity 28.0 x 106 psi 190 GPa | Thermal Conductivity 212°F (100°C) 6.8 BTU/Ft-hr°F 12.9 W/m-°K Melting Range 2372 – 2534°F 1300 – 1390°C Electrical Resistivity 33.5 Microhm-in at 68°C 95.2 Microhm-cm at 20°C |

DIN 1.4539 Ring Type Joint Flanges Thermal Composition

Properties | Metric | Imperial |

Thermal expansion coefficient (@0-100°C/32-212°F) | 10.4 µm/m°C | 5.78 µin/in°F |

Thermal conductivity | 21.6 W/mK | 150 BTU in/hr.ft².°F |

ANSI B16.5 SS F904L RTJ Flange Dimensions Chart

Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

AS4087 | PN14 | 95 | 67 | 4 | M12 | 14 |

AS 2129 Flange | Table C | 95 | 67 | 4 | 13 | 14 |

Table D | 95 | 67 | 4 | 13 | 14 | |

Table E | 95 | 67 | 4 | 13 | 14 | |

Table F | 95 | 67 | 4 | 13 | 14 | |

Table H | 114 | 83 | 4 | 16 | 17 | |

Table J | 114 | 83 | 4 | 16 | 17 | |

ANSI B16.5 | ANSI 150 | 89 | 60 | 4 | 13 | 16 |

ANSI 300 | 95 | 67 | 4 | 13 | 16 | |

ANSI 600 | 95 | 67 | 4 | 13 | 16 | |

ANSI 900 | 121 | 83 | 4 | 19 | 22 | |

ANSI 1500 | 121 | 83 | 4 | 19 | 22 | |

ISO 7005 (DIN) Flange | PN6 | 80 | 55 | 4 | M10 | 11 |

PN10 | 95 | 65 | 4 | M12 | 14 | |

PN16 | 95 | 65 | 4 | M12 | 14 | |

PN20 | 90 | 60.5 | 4 | M14 | 16 | |

PN25 | 95 | 65 | 4 | M12 | 14 | |

PN40 | 95 | 65 | 4 | M12 | 14 |

Huge Inventory Of Stainless Steel 904L Flanges

ASTM B649 904L Expander Flanges | ASME SB649 904L High Hub Blind Flanges |

ASTM B649 Gr 904L Weld Neck Flanges A / B | ASTM B649 Grade 904L Forged Flanges |

ASTM B649 904L Ring Type Joint Flanges | ASME SB649 904L Tongue & Groove Flanges |

SS 904L Reducing Flanges | ASTM B649 Gr 904L Orifice Flanges |

ASTM B649 Type 904L Flat Flanges | Stainless Steel 904L Spades Ring Spacers Flanges |

ASTM B649 904L Forging Facing Flanges | ASTM B649 Grade 904L BLRF Flange |

SS 904L Long Weld Neck Flanges | ASTM B649 Grade 904L Spectacle Blind Flanges |

Stainless Steel 904L Spectacle Blind Flangese | Stainless Steel 904L Square Flanges |

ASTM B649 Type 904L Expander Flanges | Stainless Steel ASTM B649 904L Ring Type Joint Flanges |

ASTM B649 904L Tongue & Groove Flanges | ASTM B649 904L Stainless steel Reducing Flanges |

Stainless Steel F904L Weld Neck Flange Pressure Gauge

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |