When it comes to working with pipes, understanding pipe schedules is crucial. Pipe schedules are standardized specifications that determine the wall thickness and pressure ratings of pipes. By referring to a Pipe Schedule Chart, you can easily identify the appropriate pipe for your specific application. In this comprehensive guide, we will explain the basics of Pipe Schedules Chart and provide an overview of the most commonly used schedules.

The schedule system is widely used in the piping industry to standardize the thickness of pipes for various applications. Understanding the pipe thickness schedule is crucial for engineers, designers, and professionals working with pipes. In this guide, we will provide a comprehensive overview of the schedule system, its significance, and how it is determined.

What is a Pipe Schedule?

A pipe schedule is a numerical designation that indicates the wall thickness of a pipe. It also determines the pressure rating of the pipe. The schedule number is often followed by the abbreviation “SCH” to denote a pipe schedule. Pipe schedules are important because they ensure compatibility and safety in various industries such as plumbing, oil and gas, chemical processing, and more.

The pipe schedule formula:

Sch.=P/[ó]t×1000

P is the Designed pressure, units in MPa;

[ó]t is Allowable stress of materials under design temperature, Units in MPa.

Understanding Pipe Schedule Chart

A pipe schedule chart is a reference tool that lists various pipe schedules along with their corresponding wall thicknesses and pressure ratings. It typically includes information such as schedule number, outside diameter, wall thickness, and weight per foot.

Here is an overview of the most commonly used pipe schedules:

- Schedule 5 (SCH 5): This schedule is used for light wall pipes with a relatively thin sch 5 pipe thickness. It is commonly found in applications that require low-pressure conveying of fluids.

- Schedule 10 (SCH 10): This schedule has a slightly thicker wall compared to Schedule 5. It is suitable for applications that involve moderate pressure and temperature conditions.

- Schedule 40 (SCH 40): Schedule 40 is one of the most widely used pipe schedules. It has a medium wall thickness and is commonly used in plumbing, water supply, and HVAC systems.

- Schedule 80 (SCH 80): With a thicker wall than Schedule 40, Schedule 80 pipes are designed for high-pressure applications, such as oil refineries, chemical plants, and industrial processes.

- Schedule 160 (SCH 160): This schedule has an extra thick wall and is primarily used for extremely high-pressure applications that require robust pipe construction.

It’s important to note that higher schedule numbers indicate thicker walls and higher pressure ratings. However, the inside diameter of the pipe decreases as the wall thickness increases.

Steel Pipe Dimensions Chart (Size Chart)

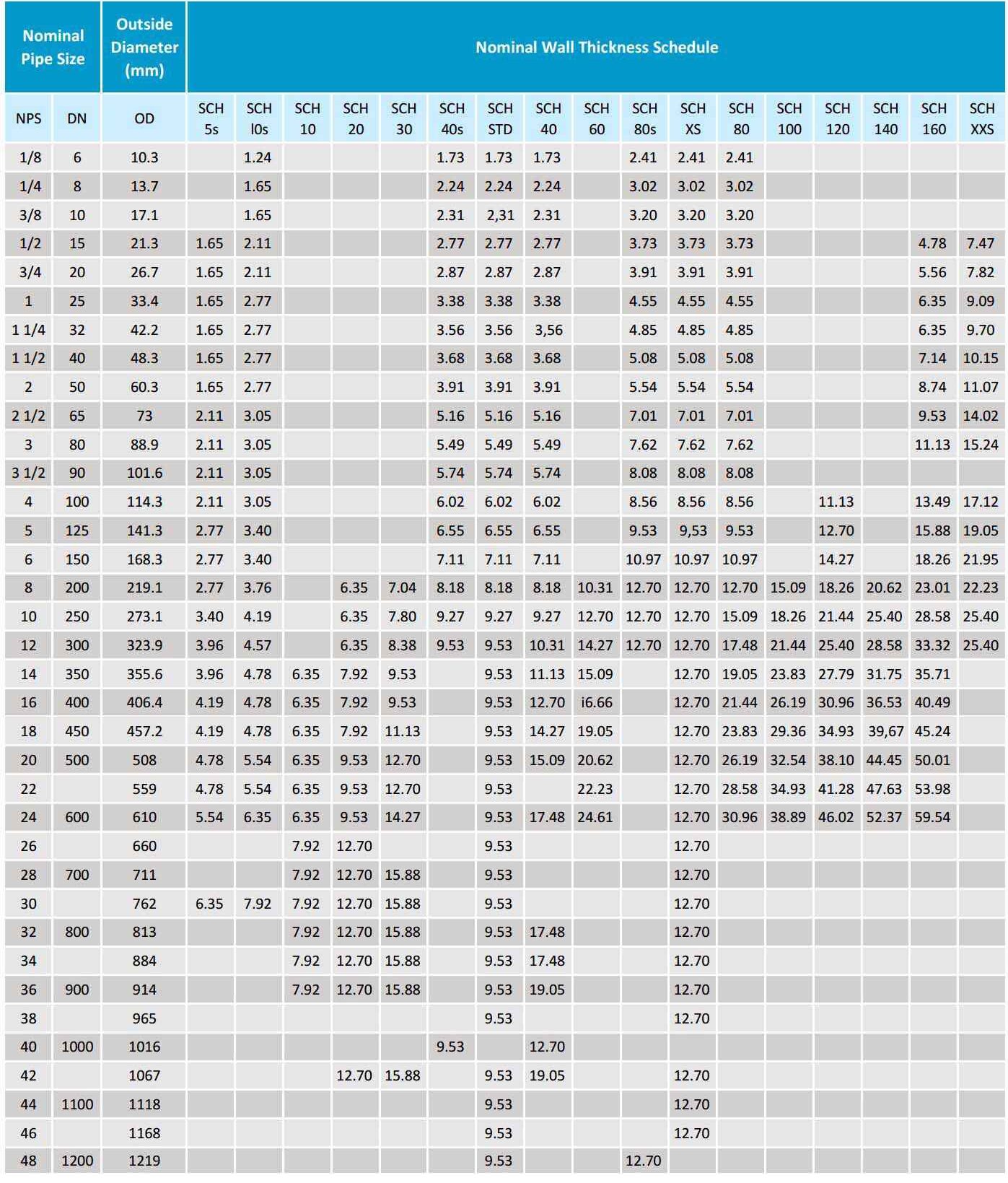

Pipe Schedule Chart unit in mm as below, view here for Pipe Schedule Chart in inch.

Dimension standards for steel pipe

There are different standards to describe the steel pipe size, OD and wall thickness. Mainly are ASME B 36.10, ASME B 36.19.

Relevant standard specification ASME B 36.10M and B 36.19M

Both ASME B36.10 and B36.19 are the standard specification for the dimensions of the steel pipe and accessories.

ASME B36.10M

The standard covers the standardization of steel pipe dimensions and sizes. These pipes includes seamless or welded types, and applied in high or low temperature and pressures.

The pipe distinguished from tube (Pipe vs Tube), here the pipe is specially for pipeline systems, fluids (Oil and gas, water, slurry) transmissions. Use the standard of ASME B 36.10M.

In this standard, the pipe Outer Diameter smaller than 12.75 in (NPS 12, DN 300), pipe actual diameters is larger than NPS (Nominal Pipe Size)or DN (Nominal Diameter).

On the hand, for steel tube dimensions, the actual outside diameter same with pipe number for all sizes.

Why pipe size smaller to NPS 12 (DN 300) have different OD

First, we need to admit that all pipe size should be identified as nominal pipe size (NPS).

Second, for NPS 1/8 (DN 6) to NPS 12 (DN 300), these are based on a standard outside diameter (O.D.) This O.D. was originally selected to specify pipe dimension, but as the pipe always have an wall thickness and internal diameter (ID). For small pipe, there is a different size between OD and ID (Wall thickness), but as the pipe dimensions became larger, the OD and ID approximately to become equal.

As there is no such relation between the old standard thickness (O.D.) and Nominal Size, so both of them accepted by standard ASME B 36.10 M.

Steel Pipe Schedule

In ASME B36.10M, Pipe schedule identified as Standard (STD), Ex-Standard (XS), or Double Extra Strong(XSS); Or with Schedule No. 5, 10, 20, 30, 40, 80, 120, 160.

ASME B36.19M

ASTM B36.19M is for the stainless steel pipe dimensions, included seamless and welded types as the same.

This dimension standard mostly is same with ASTM B36.10M. Wherever the different part is:

a. For NPS 14 to NPS 22 (DN 350-550), schedule 10S;

b. NPS 12 of Schedule 40S

c. NPS 10 and 12 of schedule 80S.

Above mentioned pipe thickness is different with B36.10M, so suffix “S” is used here.

Ways of express pipe dimensions

1. For Pipe wall thickness: Use Steel Pipe Schedule, like schedule 40 steel pipe, schedule 80 pipe.

2. For pipe Diameters: Nominal Pipe Size (NPS) and DN (Nominal Diameter)

3. Pipe weight Class (WGT), LB/FT (Pounds per foot), KG/M (Kg per meter)

What is the Nominal Pipe Size (NPS)?

Nominal Pipe Size (NPS) is a North American set of standard sizes for pipes used for high or low pressures and temperatures. Pipe size is specified with two non-dimensional numbers: a nominal pipe size (NPS) based on inches, and a schedule (Sched. or Sch.).

What is DN (Nominal Diameter)

Nominal diameter also mean outside diameter. Because as the pipe wall is very thin, the outside and inside diameter of the steel pipe is almost same, so the average value of the both parameters is used as the name of the pipe diameter. DN (nominal diameter) is the general diameter of various pipe and pipeline accessories. The same nominal diameter of the pipe and pipe fittings can be interconnected, it has interchangeability. Although the value is close or equal to inside diameter of pipe, It is not the actual sense of the pipe diameter. The nominal size is represented by a digital symbol followed by the letter “DN”, and mark the unit in millimeters after the symbol. For example, DN50, a pipe with a nominal diameter of 50 mm.

DN (mm) and NPS (inch) conversion

Nominal diameter DN (mm) and NPS (inch) conversion

1. Conversion DN ( mm ) that requires separate memory

|

DN (mm)

|

6

|

8

|

10

|

15

|

20

|

25

|

32

|

40

|

50

|

65

|

80

|

|

NPS(inch)

|

1/8

|

1/4

|

3/8

|

1/2

|

3/4

|

1

|

1 1/4

|

1 1/2

|

2

|

2 1/2

|

3

|

2. Greater than or equal to DN100 diameter and NPS conversion

DN=25*NPS;

NPS=DN/25

3. Exact conversion

1 inch =25.4 mm

Pipe Weight Class Schedule

WGT class (weight class) is an indication of the pipe wall thickness in early, but still used. It has only three grades, namely STD ( standard ), XS ( extra strong ), and XXS ( double extra strong ).

For the earlier production pipe, each caliber has only one specification, called standard tube (STD). In order to deal with high pressure fluid, the thickening pipe (XS) appeared. XXS ( double extra strong ) pipe appeared to handle the higher pressure fluid. People began to require the use of more economical thin-walled pipe until the emergence of new materials processing technology, then gradually appeared the above pipe number. The corresponding relation between pipe schedule and weight class, refer to ASME B36.10 and ASME B36.19 specification.

How to describe steel pipe dimensions and size correctly?

For example: a. Expressed as “pipe outside diameter × wall thickness”, such as Φ 88.9mm x 5.49mm (3 1/2” x 0.216” ). 114.3mm x 6.02mm (4 1/2” x 0.237”), length 6m (20ft) or 12m (40ft), Single Random Length (SRL 18-25ft), or Double Random Length (DRL 38-40ft).

b. Expressed as “NPS x Schedule”, NPS 3 inch x Sch 40, NPS 4 inch x Sch 40. Same size as above specification.

c. Expressed as “NPS x WGT Class”, NPS 3 inch x SCH STD, NPS 4 inch x SCH STD. Same size above.

d. There is another way, in North America and South America, usually use “Pipe Outer Diameter x lb/ft” to describe pipe size. As OD 3 1/2”, 16.8 lb/ft. lb/ft is pound per feet.

Pipe Material Considerations

In addition to pipe schedules, the material used for the pipe also plays a critical role in determining its suitability for specific applications. Common materials for pipes include steel, copper, PVC (polyvinyl chloride), and stainless steel. Each material has its own advantages and limitations, so it’s essential to choose the right material based on factors such as corrosion resistance, temperature resistance, and mechanical strength.

Conclusion

A pipe schedule chart is a valuable tool for anyone working with pipes. It provides vital information about wall thickness and pressure ratings, allowing you to select the appropriate pipe for your needs. By understanding pipe schedules and considering the material requirements, you can ensure the safety and efficiency of your piping systems. Always consult the appropriate codes, standards, and industry guidelines when selecting and installing pipes to ensure compliance with regulations and best practices.