Alloy Steel Nippolet Flange, Chrome Moly Pipe Flanges, Alloy Steel Spacer Flange, Alloy Steel Pipe Flanges, ANSI B16.5 Alloy Steel Orifice Flange, ANSI Alloy Flanges, Alloy Steel Slip On Flanges Supplier in Mumbai, India.

Alloy Steel Nippolet Flange, Chrome Moly Pipe Flanges, Alloy Steel Spacer Flange, Alloy Steel Pipe Flanges, ANSI B16.5 Alloy Steel Orifice Flange, ANSI Alloy Flanges, Alloy Steel Slip On Flanges Supplier in Mumbai, India.

Table of Content

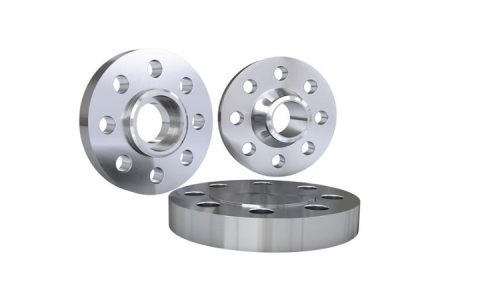

Manufacturer & Supplier of Alloy Steel Flanges

Mahavir Metals India is known for making, exporting, supplying, and trading Alloy Steel Pipe Flanges. These are available in different sizes, designs, and shapes to meet the needs of our valued customers. We also have the same thing in different grades, such as Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges, Alloy Steel Flanges If needed, these Alloy Steel Slip On Flanges can be machined, shot-peened, and polished in their as-built or stress-relieved states, where rust is the most obvious sign of corrosion. Solution annealing isn't needed for our Alloy Steel Threaded Flanges because the mechanical properties in their "as-built" state are what we want. One exception is that these Alloy Steel Weld Neck Flanges have about 24 percent chromium and can be used to stop scaling at temperatures up to 1100 Degree C. Our Alloy Steel Blind Flanges are mostly caused by environmental factors like wind, pollution from factories, and high temperatures. The problem is worse near the sea, which is a major source of salt water pollution. The high chromium content of these Alloy Steel Socket Weld Flanges makes them resistant to wet corrosion, and it also makes them strong at high temperatures and less likely to scale at high temperatures.

Depiction of the material used -

Alloy steel contains small amounts of one or more alloying elements, such as silicon, nickel, copper, chromium, manganese, and aluminium. This alloy has special properties that carbon steel doesn't have. Because it is easy to get, works well mechanically, and is easy to process, it is most often used in the workhouses of industries.

Features of the flanges -

There are a lot of things about Alloy steel flanges that make them the better choice in the industries. These qualities are excellent resistance to corrosion, high weldability, durability, strength, long life, and resistance to corrosion that causes pits. Our clients have told us how much they like our products because they are well-made and of good quality..

The production process of the flanges-

Alloy steel flanges are made from a collection of high-quality alloys. This alloy is tested by an expert to make sure that no low-quality alloy is used to make the flanges. The experts are hired to keep an eye on how the organisation works and to make sure the product is of good quality. These experts encourage the worker to do the job as quickly and well as they can so that the organisation can reach its goal. For the best quality flanges to be made, all of the rules for making them are followed. Sets of national and international quality standards are used to decide the ranges.

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary, Fort Collins, Corona, Springfield, Jackson, Alexandria, Hayward, Clarksville, Lakewood, Lancaster, Salinas, Palmdale, Hollywood, Springfield, Macon, Kansas City, Sunnyvale, Pomona, Killeen, Escondido, Pasadena, Naperville, Bellevue, Joliet, Murfreesboro, Midland, Rockford, Paterson, Savannah, Bridgeport, Torrance, McAllen, Syracuse, Surprise, Denton, Roseville, Thornton, Miramar, Pasadena, Mesquite, Olathe, Dayton, Carrollton, Waco, Orange, Fullerton, Charleston, West Valley City, Visalia, Hampton, Gainesville, Warren, Coral Springs, Cedar Rapids, Round Rock, Sterling Heights, Kent, Columbia, Santa Clara, New Haven, Stamford, Concord, Elizabeth, Athens, Thousand Oaks, Lafayette, Simi Valley, Topeka, Norman, Fargo, Wilmington, Abilene, Odessa, Columbia, Pearland, Victorville, Hartford, Vallejo, Allentown, Berkeley, Richardson, Arvada, Ann Arbor, Rochester, Cambridge, Sugar Land, Lansing, Evansville, College Station, Fairfield, Clearwater, Beaumont, Independence, Provo, West Jordan, Murrieta, Palm Bay, El Monte, Carlsbad, North Charleston, Temecula, Clovis, Springfield, Meridian, Westminster, Costa Mesa, High Point, Manchester, Pueblo, Lakeland, Pompano Beach, West Palm Beach, Antioch, Everett, Downey, Lowell, Centennial, Elgin, Richmond, Peoria, Broken Arrow, Miami Gardens, Billings, Jurupa Valley, Sandy Springs, Gresham, Lewisville, Hillsboro, Ventura, Greeley, Inglewood, Waterbury, League City, Santa Maria, Tyler, Davie, Lakewood, Daly City, Boulder, Allen, West Covina, Sparks, Wichita Falls, Green Bay, San Mateo, Norwalk, Rialto, Las Cruces, Chico, El Cajon, Burbank, South Bend, Renton, Vista, Davenport, Edinburg, Tuscaloosa, Carmel, Spokane Valley, San Angelo, Vacaville, Clinton, Bend, Woodbridge.

Alloy Steel Flanges Specifications

| Specifications | Alloy Steel Flanges – ASTM A182 / ASME SA182 |

| ASME B16.5 Alloy Steel Flanges size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Alloy Steel Flanges Standards | BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Alloy Steel Flanges Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Alloy Steel Flanges Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Alloy Steel Flanges Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Alloy Steel Flanges Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Alloy Steel Flanges Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Alloy Steel Pipe Flanges Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of Alloy Steel Flanges |

|

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations Alloy Steel Flanges Threaded Flanges, Socketweld Flanges, Slip-On Flanges, Blind Flanges, Weld Neck Flanges |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Specialized manufacturer of |

|

| Alloy Steel Flanges Standard | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

|

| Key markets and industries for Alloy Steel Flanges |

|

Alloy Steel Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F1 | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| Alloy Steel F5 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

| Alloy Steel F11 | 0.5-0.15 | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 1.0-1.5 | 0.44-0.65 |

| Alloy Steel F12 | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| Alloy Steel F22 | 0.50.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| Alloy Steel F91 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

Alloy Steel Plate Flanges Mechanical Properties

Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

Alloy Steel F1 | 275 | 485 | 20 % |

Alloy Steel F5 | 275 | 485 | 20 % |

Alloy Steel F9 | 380 | 585 | 20 % |

Alloy Steel F11 | 205 | 415 | 20 % |

Alloy Steel F12 | 275 | 485 | 20 % |

Alloy Steel F22 | 205 | 415 | 20 % |

Alloy Steel F91 | 380 | 585 | 20 % |

x