Inconel Steel 601 Flanges Manufacturer in India

HOME → Our Products → Flanges → Inconel Steel Products → Inconel Steel 601 Flanges Manufacturer

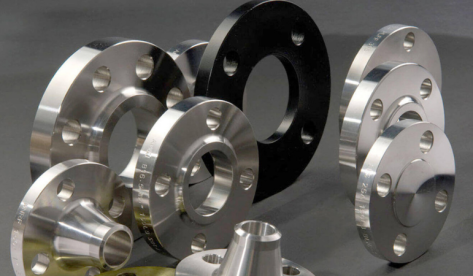

Alloy 601 Flanges,, WERKSTOFF NR. 2.4851 Flanges, ASTM B564 Inconel 601 Flanges Inconel 601 Flanges Manufacturers in India, ANSI B16.5 Inconel Alloy 601 Flanges, Inconel Alloy 601 Flanges, DIN 2.4851 Flange, UNS N06601 Flange Supplier of Inconel Alloy 601 Flanges in Mumbai, India

Inconel Alloy 601 SORF Flanges, Inconel 601 WNRF Flange, Inconel Alloy 601 Pipe Flanges Stockist, Inconel 601 Slip On Flange, Global Exporter of Inconel 601 Flanges, Inconel 601 SWRF Flanges, Inconel 601 Alloy RTJ Flanges in India, Inconel 601 Socket Weld Flanges, Inconel 601 Flange

Manufacturer & Supplier of Inconel Steel 601 Flange

Mahavir Metals India is a company that specializes in providing high-quality Inconel 601 flanges that are made from just the highest-quality raw materials. Flanges are also manufactured with the most up-to-date technology and contemporary equipment, ensuring that the product quality is unquestionably higher. The flanges are offered to the consumers in a variety of specifications that easily meet the needs of all purchasers. The product is exclusively sold at fair prices to its customers. The flanges are delivered to the buyer with the sincere dedications, efforts, and support of the professional and quality control team, ensuring longevity and durability.

Without a doubt, the product's exceptional quality allows it to have a number of useful features. It has corrosion resistance, exquisite finishes, is simple to install, is resistant to aqueous corrosion, has strong mechanical strength, and can withstand heavy loads, among other things.

Before supplying the goods, the industry ensures that the created assortment of flanges is thoroughly tested. To ensure the quality of manufacture, each product is subjected to rigorous testing. This prevents the faulty product from reaching the customer. PMI test, flattening test, mechanical test, macro test, chemical analysis, IGC test, flaring test, micro test, hardness test, and pitting resistance test were all carried out.

The paperwork that is given to buyers when the goods are delivered is simply to ensure that the transaction is done honestly. Fumigation certification, commercial invoice, and packaging list are among the documents; guarantee letter, material traceability report, heat treatment chart, QAP, raw material test report, and so on.

Standard Specification for Inconel 601 Flanges

ASTM B564 / SB564M – specification covers nickel alloy flanges. These alloys are classified into different grades according to their chemical composition.

ANSI B16.5 – standard covers alloy Pipe Flanges and Flanged Fittings from NPS 1/2 through NPS 24 Metric/Inch in pressure class 150 to class 2500.

ANSI/ASME B16.47 – Term B16.47 or B 16 47 or ANSI B 16 47 are all used interchangeabily and refers to the same standard. ASME B16.47(Large Diameter Steel Flanges) is a standard for large diameter steel pipe flanges sized from NPS 26 through NPS 60.

ANSI B16.48 – Standard covers pressure–temperature ratings, materials, dimensions, tolerances, marking, and testing for operating line blanks in sizes NPS 1⁄2 through NPS 24 for installation between ASME B16.5 flanges in the 150, 300, 600, 900, 1500, and 2500 pressure classes.

Inconel 601 Flanges Chemical Properties

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| 601 | 0.15 | 1.00 | 0.5 | 0.015 | 1.0 | Bal | 58.0 – 63.0 | 21.0 – 25.0 |

Inconel 601 Flanges Mechanical Properties

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 45,000 , MPa – 310 | Psi – 80,000 , MPa – 550 | 30 % |

Equivalent Grades of ASME SB564 Inconel 601 Flanges

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 601 | N06601 | 2.4851 | NC23FeA | NiCr23Fe | NCF 601 | NA 49 | XH60BT | ЭИ868 |