Inconel Steel 601 Sheets/Plate Manufacturer in India

HOME → Our Products → Sheets → Inconel Steel Products → Inconel Steel 601 Sheets/Plate Manufacturer

Inconel Alloy 601 Hot Rolled (HR) Sheet & Plates, ASME SB 168 Inconel 601 Sheet, Inconel 601 Cold Rolled (CR) Sheet & Plate, Inconel 601 Sheet and Plate Supplier in india Inconel 601 Plates Stockists in Mumbai

Inconel 601 Circles, Inconel 601 Coils, Inconel Alloy 601 Shim Sheets, Inconel 601 Perforated Sheets Supplier in Mumbai, ASTM B168 Inconel 601 Sheet & Plate Exporter, Inconel 601 Export Quality Sheet & Plate Stockists in India.

Manufacturer & Supplier of Inconel Steel 601 Sheets/Plate

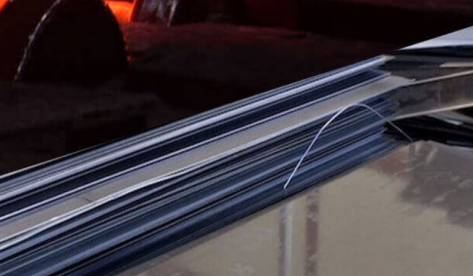

Inconel 601 plate Manufacturer in india because it retains its high mechanical qualities even when subjected to high-temperature environments. However, the DIN 17750 2D Plate has excellent heat and corrosion resistance, and it performs exceptionally well when exposed to high temperatures, up to a maximum temperature of 1200 degrees Celsius.

Standard engineering material: The Inconel N06601 4mm Thick Plate has a high tensile strength, is easy to work with, and is resistant to corrosion even in water.

Other things about the 2.4851 Inconel 601 Clad Plate are that it is easy to work with and has a high resistance to carburizing. If you use Inconel 601, you can be sure that it will stay together well. When you do cold work on the inconel 601 Din 2.4851 Flat Plate, you can make the metal stronger and harder by doing this. This is another reason why the SB 168 Alloy 601 Nickel Slitting Coil is more appealing. When exposed to oxidative conditions, the metal forms a tightly bound oxide scale. When the Alloy 601 Inconel Polished Plate is heated and then cooled, a layer of oxide forms on the surface. This oxide scale makes the alloy more resistant to spalling, even in very hot and cold places like this.

Inconel UNS No 6601 Hot Rolled Plate is made of nickel, which makes it very strong at higher temperatures. This material can keep its ductility even after long periods of use. Alloy Inconel 601 Foil is very easy to shape, machine, and weld because it is very strong. As a rule, the metal can be welded by using techniques like shielded metal welding, submersed arc welding, and the gas metal arc welding method as well.

When the Inconel 6601 Strip Tape is used, it must be in a solution-treated state to make it easier to machine. The Inconel 601 alloy can be machined in the same way as welding. Machining procedures that are used for iron-based alloys can be used for this alloy. It's common for machining to be done on the ASTM B168 Inconel 601 Alloy Sheet with the help of commercial coolants. The Inconel 601 UNS N06601 Strip can be used for high-speed operations like milling, grinding, or turning. Water-based coolants can be used to keep the strip clean. Even though for things like tapping, drilling, boring, or broaching, heavy lubricants are used on Inconel 601, they aren't used for everything.

A shim sheet made of Alloy 601 UNS N06601 has good creep rupture strength, and the alloy can be used to make equipment that needs to be exposed to high temperatures for a very long time. The alloy's usefulness for high-temperature applications is boosted by its resistance to not only oxidation but also other types of corrosion that happen when the metal is exposed to high temperatures for a long time.

Even at high temperatures, Alloy Inconel 601 B168 Shim Stock has better mechanical properties than Inconel 600.

Combining Alloy 601 Shim Sheet's great resistance to corrosion with other high-temperature corrosion makes the metal useful in a lot of different ways. This is because the metal can be used in many different ways because of its properties.

Inconel 601 Plate Comparing Standards Specification

| Product Type | Nickel Alloy 601 Sheet & Plate |

| Specification | ASTM B168 / ASME SB 168 UNS N06601 |

| Tolerances (width / thickness) |

|

| Manufacturing Standard |

|

| Dimensions and sizes |

|

| Length | 2m, 2.44m, 3m, or as required |

| Thickness range | 0.1 to 100 mm Thk |

| Width | 10 – 2500mm |

| Hardness chart | Half Hard, Soft, Quarter Hard, Hard, Spring Hard |

| Other Forms available | Plate, Sheet, Coils, Foils, Strip, Flats, Rolls, Blank (Circle), sheared, annealed, descaled, Clad Plate, Plain Sheet, Flat Sheet, Rolling Sheet, Rolling Plate, soft annealed, Flat Shim, Shim Sheet, tread plate, Checker Plate |

CHEMICAL COMPOSITION OF ASTM B168 INCONEL 601 SHEET PLATE

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

MECHANICAL PROPERTIES OF ASME SB168 INCONEL 601 SHEET PLATE

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Inconel 601 material equivalent grades

| Material | EN | WERKSTOFF NR. | UNS | BS | GOST | JIS | AFNOR |

| Inconel 601 Sheet/ Plate | NiCr23Fe | 2.4851 | N06601 | NA 49 | XH60BT | NCF 601 | NC23FeA |