Inconel 600 Tube Manufacturer in India

HOME → Our Products → Tube → Inconel Steel Products → Inconel 600 Tube Manufacturer

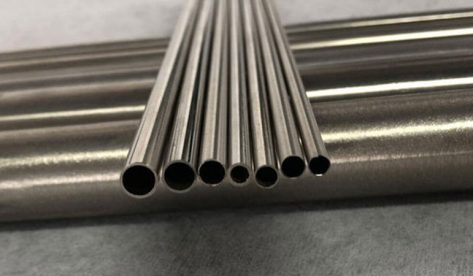

Inconel 600 Seamless Tubes, Inconel Alloy 600 Tubes, GOST МНЖМц 28-2,5-1,5 Tube, ASTM B163 Alloy 600 Seamless Tubing, 600 Inconel Welded Tubes Suppliers and Exporters in Mumbai, India.

Dealer of ASTM B516 Inconel 600 Tube, Inconel 600® Tubing, Inconel UNS N06600 Tubing, Alloy 600 ERW Tubes Supplier, Inconel NCF 600 Tubes, Inconel WERKSTOFF NR. 2.4816 Tubing Manufacturer in India.

Manufacturer & Supplier of Inconel 600 Tube

Alloy 600 Tubes are available from Mahavir Metal Steel in a variety of sizes and shapes. Alloy 600 is a nickel-chromium alloy that exhibits excellent resistance to oxidation and corrosion at high temperatures. Nickel-chromium alloy Inconel 600 Seamless Tubes have excellent oxidation resistance at high temperatures as well as resistance to chloride-ion stress corrosion cracking, corrosion by high-purity water, and caustic corrosion. Inconel 600 Seamless Tubes are available in a variety of sizes and shapes. These Inconel 600 Welded Tubes is a nickel – chromium – iron, solid solution reinforced alloy used for applications that demand corrosion and high temperature resistance. Inconel 600 EFW Tubes is a nonmagnetic and nickel – based high temperature alloy featuring a great mix of high strength, hot and cold workability, coupled with resistance to ordinary type of corrosion. These Inconel 600 ERW Tubes are utilised for a variety of applications including furnace components, chemical and food processing, nuclear engineering, and sparking electrode applications. Stainless steel tubing, Inconel UNS N06600, was developed to withstand temperatures ranging from cryogenic to high temperatures in the region of 2000 degrees Fahrenheit. Throughout the annealed to extensively cold worked condition range, these Inconel 600 Round Tubes exhibit excellent heat resistance and are free from ageing or stress corrosion. Inconel 600 Square Tubes have excellent mechanical qualities and provide the required combination of high strength and good workability. Inconel 600 Square Tubes are available in a variety of sizes. These Inconel 600 Rectangular Tubes are also known as a nickel-chromium alloy, and they are designed to withstand temperatures ranging from cryogenic to elevated temperatures in the range of 1093 degrees Celsius.

Inconel 600 Seamless Tube/ Inconel 600 Seamless Tubing have exceptional mechanical qualities and provide a desirable combination of good workability and high strength. Inconel 600 Seamless Tube/ Inconel 600 Seamless Tubing are available in a variety of sizes and shapes.

As a result of the high nickel content, it is resistant to corrosion by a wide range of organic and inorganic substances, as well as being almost impervious to chloride-ion stress-corrosion cracking.

While ASTM B167 UNS N06600 has a high chromium concentration, which puts it far ahead of pure nickel in terms of oxidation resistance, it also has a high nickel content, which gives it excellent corrosion resistance when subjected to reducing circumstances. It exhibits significant levels of stress and salt water resistance, as well as resistance to exhaust fumes and the majority of organic acids and chemicals.

Inconel 600 Tube Specification Chart

Standard | ASTM, AISI, GB, JIS, customers’ requests available |

Size | Round Tube: OD: 16-119mm or customized |

Thickness | 0.25mm-3.0mm |

Length | 6m or according to customers’ request |

Sample | Free sample is available, but freight should be paid by you |

Tolerance | Outer diameter: ±0.2mm Thickness: ±0.05mm Length: ±0.5mm |

Ends | In plain end or bevelled ends or as your requirements |

Marking | Tubing are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

Welding Line Type | ERW (Electrical Resistance Weld) |

Finishing | A. Sanded B. Gloss #400,Mirror #600 – #1000 D. Wood Grain C. Brushed E. Embossed, Threaded |

Form | ‘U’ bent, Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc |

End | Plain End, Beveled End, Treaded Tube |

Application | Decorations, constructions, food industry, etc. |

Certification | ISO, SGS |

Rectangle Pipe Size | 10*30, 10*40, 10*50, 20*10, 23*11, 24*12, 25*13, 28*25, 28*13, 29*14, 30*15, 30*20, 30*22, 34*22, 36*23, 50*25, 60*30, 75*45, 95*45 mm |

Thickness | exact 0.25, 0.28, 0.32, 0.37, 0.41, 0.51, 0.61, 0.71, 0.91, 1.11, 1.15, 1.41 mm |

Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

Round Pipe Size | 16, 17, 18, 19, 20, 21, 22, 23, 25, 28, 31.8, 35, 36, 38.1, 48, 50.8, 60, 63.5, 76.2, 89, 101, 114 mm |

Square Pipe Size | 17, 18, 19, 20, 21, 22, 23, 24, 25, 28, 30, 36, 38, 50 mm |

Length | 6m or according to customer’s request |

Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine Sand-blasting machine, etc |

Outer diameter | 6.35-219mm |

Process method | Code drawn, annealed with nitrogen protection, ultrasonic, automatic shape, polished |

Origin | West Europe / Japanese / Indian / USA / Korean / American / European |

Test Certificates | Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report |

Chemical Composition Standard of Nickel alloy 600 tubing

Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

ASTM B163 Alloy 600 Seamless Tube Mechanical Properties Chart

Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Inconel 600 Seamless Tube Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |