Stainless Steel Flanges Manufacturer In Mumbai India

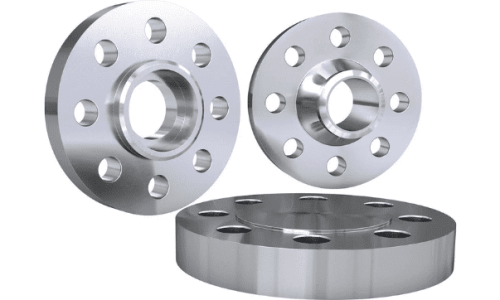

ANSI B16.5 Stainless Steel Flanges, SS Forged Flanges, ASTM A182 Stainless Steel Flange, Stainless Steel Pipe Flanges, SS Plate Flanges, Stainless Steel Flanges, Stainless Steel Flange, SS Flanges, Stainless Steel Flanges Manufacturer in Mumbai, India.

Stainless Steel Lap Joint Flanges Wholesaler, SS Orifice Flange, ASME SA182 SS RTJ Flanges, Buy Stainless Steel Threaded Flanges, SS Plate Flanges Dealer, SS Flanges Stockist, SS Forged Flanges, SS Long Weld Neck Flanges, SS SORF Flanges, ANSI B16.5 SS Blind Flanges, Stainless Steel Spectacle Blind Flanges Supplier in Mumbai, India.

Manufacturer & Supplier of Stainless Steel Flanges

SS Flange is a forged or cast ring that is used to connect different parts of a pipe or any other piece of machinery that needs a connection point in the middle. Because they are strong and have a smooth surface, these flanges are in high demand on the market. Since many generations, Mahavir Metals India has been the top maker and exporter of these SS Flanges both in India and around the world. We have a team of professionals and employees with a lot of experience and skill who work together to make SS Flanges of a high quality. These flanges are designed and made according to international and national standards and specifications. Our workers are carefully making these flanges with modern tools and advanced manufacturing methods. Our experts watch over each step and tell our workers what to do so that the best products can be made. We sell SS Flanges that can hold up well in rough and corrosive environments.

Mahavir Metals India is focusing on making sure that these flanges meet all of our customers' exact needs. Before sending these flanges out for delivery, we make sure that each one is tested under strict conditions so that they work better. We have a team of quality control experts with a lot of experience. They put SS Flanges through a number of tests to check different characteristics and parameters. During the whole process of making something, testing is done under close watch. We set up inspections by third parties for our clients. We have a large number of SS Flanges stored in our warehouse, which is very safe. In our warehouse, flanges can be kept for a long time, and urgent needs from industries around the world can be met here.

At our company, we put a lot of thought into how the SS Flanges are packed. We promise that these flanges will arrive without damage because we wrap them in high-quality packaging material. We also offer customized packaging options based on what our customers want so that we can deliver their flanges without any damage. We keep these flanges from getting broken or rusty until they are sent to the customer. SS Flanges are shipped before the deadline because they can be moved easily. We always try to keep our relationships with our customers professional and honest by giving them the best products and services on the market. We use the best transportation in the business to make sure the products get there safely and on time.

Specification of Stainless Steel Flanges

A182 Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

Stainless Steel Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

SS Grade Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

ASTM A182 Stainless Steel Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

ASME SA 182 Flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

ASME SA182 Stainless Steel Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

A182 Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

Most common types of ASTM A182 Stainless Steel Flange | Forged / Threaded / Screwed / Plate |

Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

ASME SA182M SS Flange Production technique | Forged, Heat treated and machined |

A182 Grade Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations |

ASME A182 SS Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

ASTM A182 SS Flange Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

SS Flange Origin | Indian / West Europe / Japan / USA / Korean |

Manufacturer of Stainless Steel ASTM A182 Flange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. ASTM A182 Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange B.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British standard (BS) DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 ASTM A182 F316 Stainless Steel Flanges The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

ASME SA182M Stainless Steel Flange Uses & application | Bitumen upgraders. Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

Different Forms of ASTM A182 Stainless Steel Flanges

Stainless Steel Flanges Type | Size | |

ASTM A182 SS Slip-On Flanges | ASTM A182 SS Threaded Flanges | Sizes 1/8″ – 36″ Raised Face or Flat Face |

ASTM A182 SS Weld Neck Flanges | ASTM A182 SS Socket Weld Flanges | |

ASTM A182 SS Blind Flanges | ASTM A182 SS Reducing Flanges | |

ASTM A182 SS Lap Joint Flanges | ASTM A182 SS Plate Flanges | |

ASTM A182 SS Orifice Flanges | ASTM A182 SS Forged Flanges | |

ASTM A182 SS Ring Type Joint Flanges | ASTM A182 SS Square Flanges | |

Stainless Steel Flanges Weight Chart

Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Stainless Steel Flanges Chemical Composition

Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

SS 316 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 16 – 18 | 2 – 3 | 10 – 14 | 0.1 max |

Stainless Steel Pipe Flanges Mechanical Properties

Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |