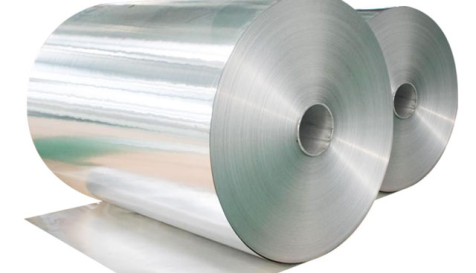

Overview of 1070 Aluminium Coil

Aluminum, with its exceptional attributes and specifications, is widely used in various industrial applications. Being a lightweight metal, it boasts only one-third of the density of steel and brass. Its corrosion resistance in marine environments is excellent, and anodizing can further enhance its scratch resistance. The 1070 aluminum coils find widespread use in industries due to aluminum's high reflectivity.

The remarkable characteristics of aluminum make these coils highly valuable across different industrial sectors. Its excellent electrical and heat conductivity, approximately 62% of annealed copper, adds to its appeal. Moreover, Aluminum 1070 coils are non-toxic, making them safe for various food applications, and they are readily recyclable.

At Mahavir Metals India, we are a leading exporter, and supplier of top-notch Aluminium 1070 Coils. Our commitment to using efficient raw materials enhances the quality and performance of our aluminum coils. Our products come with unique features that are highly appreciated by our customers, including high-end finishing, accurate dimensions, timely delivery, and impressive durability. We also offer customization options to cater to the specific needs of our clients.

Our utmost priority is ensuring complete customer satisfaction regarding the quality, performance, and durability of our products.

Aluminium 1070 Coils, Aluminium Alloy 1070 Coil, Aluminium 1070 Slitting Coils, Aluminium DIN 3.0275 Coils, Aluminium Alloy 1070 Coil Dealer in Mumbai, Aluminum 1070 Alloy (UNS A91070) Coils Manufacturer in Mumbai.

Aluminium 1070 Coils Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness : 0.2~300mm

Length : 500~10000mm

Width : 500~2500mm

Surface : Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc

Finish : Mill, Customer specific finish

1070 Aluminium Coil Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. |

| Aluminium 1070 | A91070 | 3.0275 |

1070 Aluminium Coil Chemical Composition

| Aluminium 1070 | Fe | Si | Mg | Mn | Cu | Zn | Ti | Al |

| 0.25 | 0.2 | 0.03 | 0.03 | 0.03 | 0.07 | 0.03 | 99.70 |

1070 Aluminium Coil Mechanical Properties

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Density (×1000 kg/m3) | 7.7-8.03 | 25 | |

| Poisson’s Ratio | 0.27-0.30 | 25 | |

| Elastic Modulus (GPa) | 190-210 | 25 | |

| Tensile Strength (Mpa) | 640 | 25 | cold drawn, spheroidized annealed more |

| Yield Strength (Mpa) | 495 | ||

| Elongation (%) | 10 | ||

| Reduction in Area (%) | 45 | ||

| Hardness (HB) | 192 | 25 | cold drawn, spheroidized annealed more |