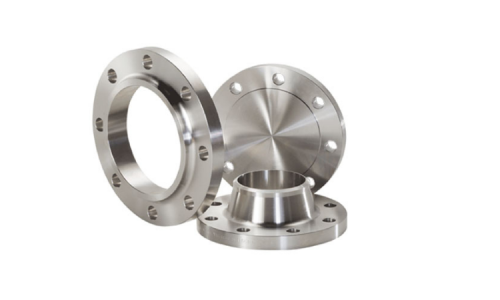

Nickel Alloys Flange Manufacturer In Mumbai India

Nickel Alloy ASTM B564 200 Threaded Flanges, EN-1092 Nickel 200 Forged Flanges, 201 Alloy Lapped joint Flanges, Werkstoff No 2.4066 Nickel Socket Weld Flanges, ANSI B16.5, B16.48, BS 10, ANSI B16.47, BS4504, Manufacturer Of ASTM B564 201 Alloy Plate Flange in Mumbai, India.

Nickel WNRF Flanges Exporter, Nickel DIN 2.4068 Flat Flange, Stockholder Of Nickel Alloy 201 RTJ Flange, Nickel Alloy UNS N02200 Industrial Flanges, ASME SB564M Nickel Alloy 200 Class 300 Flange Wholesaler, 200 Nickel Alloy EN 1092-1 Flanges Traders in India.

Manufacturer & Supplier of Stainless Steel Flanges

Mahavir Metals India is a well-known business that makes, sells, and exports Nickel Flanges. Our Flanges are in high demand across all industries because they have perfect dimensions and work better. So, we always keep a lot of stock on hand so we can meet our customers' needs in an emergency. We offer these Flanges in different sizes, shapes, dimensions, and lengths. We also make custom products for our clients based on the sizes and shapes they need. Our clients can buy these Flanges from us at prices that are fair.

The purest metals are used to make these Flanges so that they are the most durable, strong, and many other things. Nickel, chromium, copper, and molybdenum are all types of metal. Because these metals are in it, it has a good yield strength, a good tensile strength, and a good corrosion resistance. These Nickel Alloy Welding Neck Flanges have parts and structures that are resistant to corrosion in general. We at Mahavir Metals India make these Nickel Flanges using high-quality raw materials that are mostly chosen with the help of the newest tools and methods. Our team is very good. Our expert team members have been trained well and know a lot about how to make these Flanges to the highest quality standards.

We at Mahavir Metals India always look at international and national standards and specifications to make sure that the quality and quantity of our products stay the same. We always do our best to make sure we have the best products that can be used in many different industries. We always think about what our clients want and need and work to meet those needs so that we can give them a better product. Before delivering the finished product, we at Mahavir Metals India also do destructive and non-destructive tests on it. These tests are done with the help of our most knowledgeable members. And once we're happy with how well these Nickel flanges meet our standards for quality, we package them. We use the best quality packaging materials to put these Flanges in their boxes. Our clients can also get different test certificates from us. We deliver Flanges safely to our clients' front doors.

Nickel Flanges Specification

| B564 Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Nickel Alloy Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Alloy Grade Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ASTM B564 Nickel Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| ASME SB 564 Flange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| ASME SB564 Nickel Alloy Flange UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| B564 Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ASTM B564 Nickel Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| ASME SB564M Alloy Flange Production technique | Forged, Heat treated and machined |

| B564 Grade Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations |

| ASME B564 Nickel Alloy Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| ASTM B564 Alloy Flange Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Alloy Flange Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of Nickel Alloy ASTM B564 Flange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. ASTM B564 Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange B.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British standard (BS) DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 ASTM B564 Nickel Flanges The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| ASME SB564M Nickel Flange Uses & application | Bitumen upgraders. Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

ASME SB564 200 / 201 Nickel Alloy Flanges Equivalent Grades

Grade | C | Mn | Si | S | Cu | Fe | Ni |

Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Chemical Composition of Grade 200 / 201 Nickel Alloy Pipe Flanges

Grade | C | Mn | Si | S | Cu | Fe | Ni |

Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties of ASTM B564 Nickel Alloy 200 / 201 Plate Flanges

Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

Nickel 200 / 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |