Super Duplex Flanges Manufacturer In Mumbai, India

HOME → Our Products→ Flanges → Super Duplex Flanges

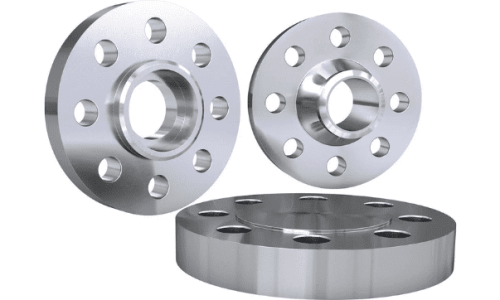

Ferritic / Austenitic Stainless Steel Pipe Flanges, Super Duplex Stainless Steel Flanges, ANSI B16.5 Super Duplex Steel Flange, Super Duplex Forged Flanges, Super Duplex Steel Socket weld Flanges Stockist, Super Duplex Orifice Flanges, Super Duplex Flanges Supplier in Mumbai, India.

Ferritic Stainless Steel Slip on Flanges, Super Duplex RTJ Flanges, Super Duplex Steel Weld Neck Flanges, ASTM A182 Super Duplex Blind Flanges, ASME SA 182 Ferritic / Austenitic Stainless Steel Lap Joint Flanges, Super Duplex Steel Long Weld Neck Flanges Exporter in India.

Manufacturer & Supplier of Super Duplex Flanges

Mahavir Metals India is a well-known company that makes and sells Super Duplex Steel Flanges of very high quality. These flanges are in high demand because they are well made and easy to work with. The strength of these Flanges and their ability to withstand high temperatures have made them more popular all over the world. We sell good Super Duplex Steel Flanges at a price that is very fair.

Chromium, nickel, and molybdenum are the chemicals that are used to make Super Duplex Steel Flanges. The Super Duplex Steel Flanges are very easy to shape and are also easy to weld. Most Super Duplex Steel Flanges may need an annealing treatment after they have been welded to make them more resistant to corrosion. One thing that can be said about Flanges is that they work well in a wide range of atmospheric conditions and in many corrosive media. The quality of these flanges meets international standards. The Super Duplex Steel Flanges have good resistance to oxidation in a wide range of temperatures. This is because the Flanges can be used to hold pressure and build structures at different temperatures.

At Mahavir Metals India, we make Super Duplex Steel Slip on Flanges that have great features like high ductility and good flexibility. They are also very durable. Our range of Flanges can be used in the marine, chemical processing, power generation, petrochemicals, and aerospace industries. We make high-quality Super Duplex Steel Flanges with the help of modern technology and tools. Because of this, it has made our flanges stronger. At our manufacturing unit, Mahavir Metals India is making Super Duplex Steel Flanges out of the best quality raw materials. The materials we use are checked for quality at the plant where they are made. At our manufacturing plant, we have a team of skilled experts who know how to develop products and help all of our workers make the best Flanges possible. The quality analysis team also checks the quality of Super Duplex Steel Flanges and keeps it up to date. After testing, the flanges that have been ordered are properly packed, and the orders are then sent to our clients within the time frame that was agreed upon.

Super Duplex Flanges Specification

Specifications | Super Duplex 2507 Flanges |

Super Duplex Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

ASME B16.5 Super Duplex Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

Main Types | Forged / Threaded / Screwed / Plate |

Flange supporting material | Gasket, Ring Joint, Flange Bolts |

Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

Super Duplex Pipe Flanges Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third-Party Inspection Report, etc |

Test | A hydrostatic testing machine, direct-reading Spectrograph,UI ultrasonic flaw detector, X-ray detector, Magnetic particle detector |

Super Duplex Flanges Equivalent Grades:

STANDARD | WERKSTOFF NR. | UNS |

Super Duplex 2507 | 1.4410 | S32750 / S32760 |

Chemical Properties of Super Duplex Flanges

Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Properties of Super Duplex Flanges

Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |